For critical manufacturing equipment, a Industrial Plug Socket Connector provides the vital link that guarantees uninterrupted power flow and operational safety across diverse industrial environments.

The Role of High-Quality Materials

Long-lasting performance begins with selecting durable materials. Housings made from UV-resistant polycarbonate or glass-reinforced nylon resist impact, chemicals, and extreme temperatures. Internally, copper or brass contacts deliver excellent conductivity while minimizing heat buildup. Sealing components—such as silicone gaskets—ensure protection against dust and moisture, achieving IP44 to IP67 ratings. Choosing premium materials reduces replacement frequency and safeguards expensive machinery from power inconsistencies.

Design Features for Operational Excellence

Efficient connector designs streamline installation and daily use. Ergonomic grips allow technicians to engage and disengage connectors quickly, even when wearing gloves. Color-coded shells help identify voltage and phase configurations at a glance, speeding up system setup. Locking mechanisms—twist locks or latch systems—prevent accidental disconnection under load. Additionally, cord reinforcements and strain relief components protect cables at stress points, extending service life and reducing maintenance needs.

Tailored Solutions with NANTE Connectors

In sectors with specialized demands, custom configurations are essential. NANTE’s range includes modular socket blocks that can be reconfigured without rewiring entire panels. Their thermal-disconnect inserts cut power when contact temperatures exceed safe thresholds, protecting downstream electronics. LED indicators embedded in couplers offer instant visual confirmation of live circuits, enhancing technician safety. Whether you require a three-pin single-phase model or a five-pin three-phase assembly, NANTE’s bespoke options meet stringent performance and compliance standards.

Compliance with Industry Regulations

Adherence to regulatory standards is non-negotiable. Industrial connectors must comply with IEC 60309, UL 1682, and NEC guidelines to ensure safe operation under rated voltage and current. Certification processes involve rigorous testing for insulation resistance, temperature rise, grounding continuity, and impact resistance. Specifying certified connectors not only mitigates liability but also ensures compatibility with existing power distribution infrastructure in facilities ranging from chemical plants to outdoor event venues.

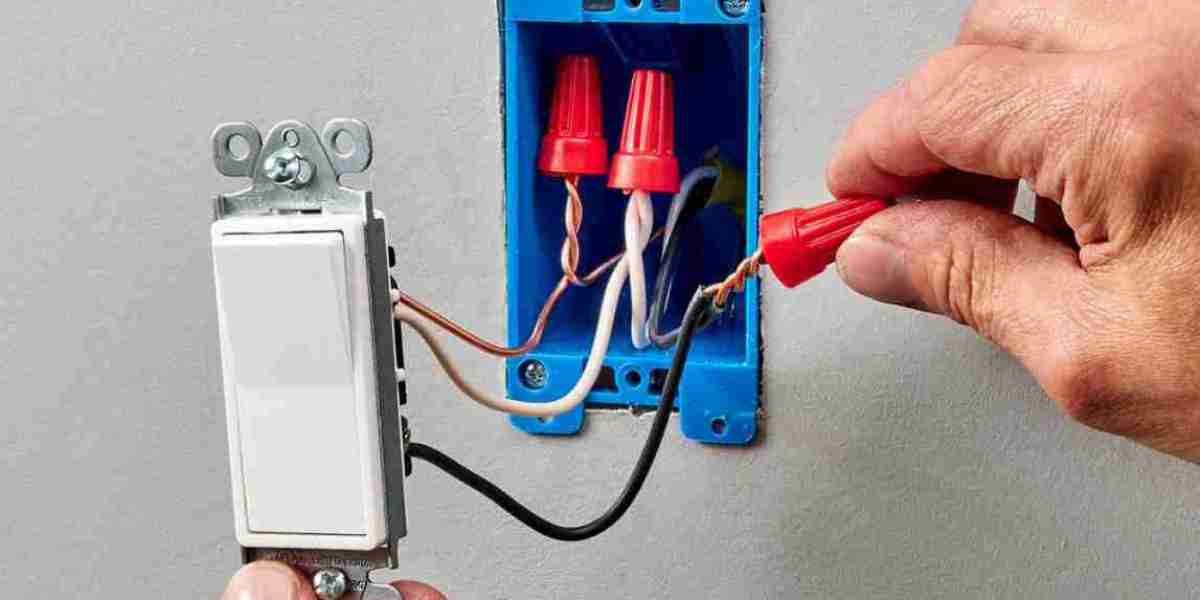

Proactive Maintenance and Inspection

Even the most robust connectors require regular attention. Establish a maintenance schedule that includes visual inspections for housing cracks, contact discoloration, or gasket wear. Use a micro-ohmmeter to detect rising contact resistance, an early sign of corrosion or deformation. Clean contacts with approved solvents and apply dielectric grease to prevent moisture ingress. Replace components showing signs of degradation before failure occurs. Training maintenance staff on proper mating and unmating techniques further reduces connector damage and enhances overall system reliability.

By combining top-tier materials, thoughtful design, regulatory compliance, and diligent upkeep, facilities can achieve seamless power delivery and minimize costly downtime. For comprehensive industrial power connection solutions, visit www.nante.com