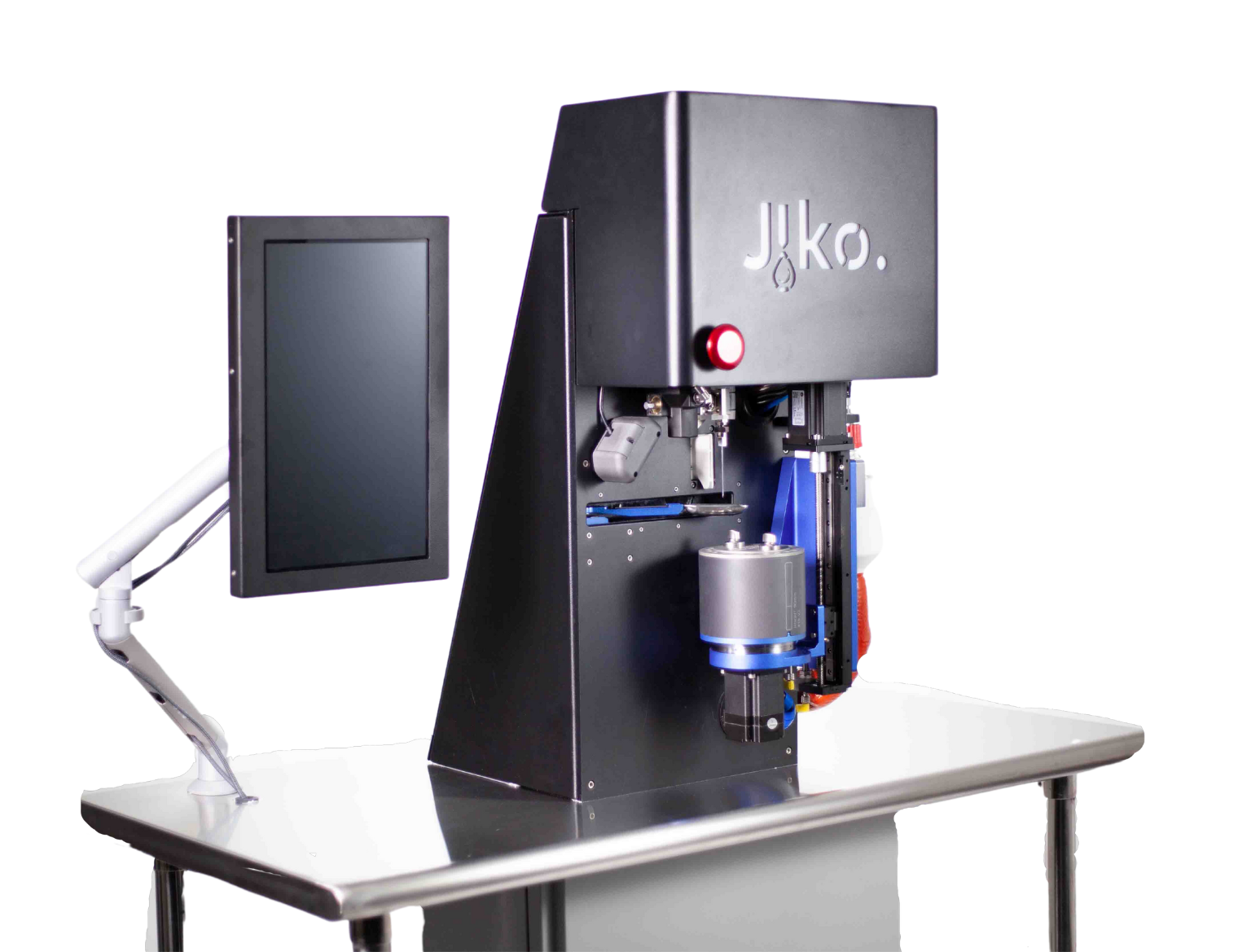

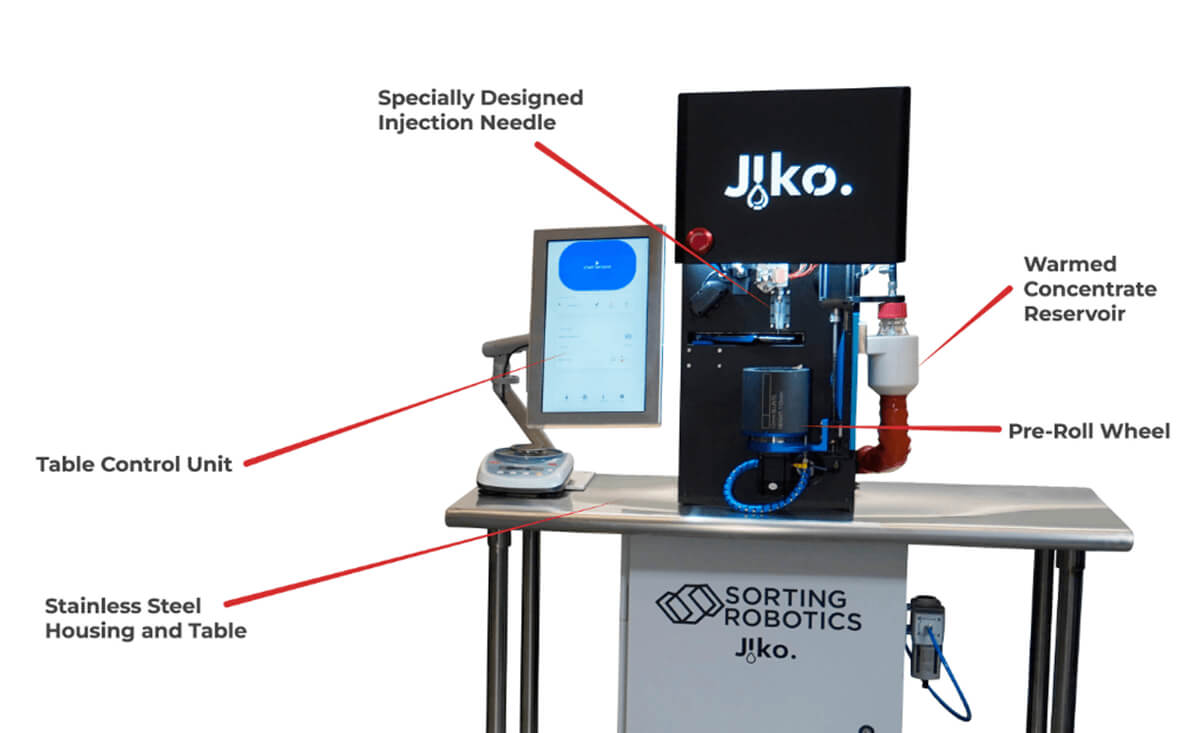

In the evolving world of cannabis production, innovation plays a crucial role in enhancing product quality and operational efficiency. One significant development is the introduction of the Jiko Automated Pre-Roll Infusion system, designed to revolutionize how cannabis pre-rolls are infused with concentrates or flavors. This article explores how Jiko compares to traditional manual pre-roll infusion methods, analyzing the benefits, challenges, and implications for producers and consumers alike.

As consumer demand for infused cannabis products grows, producers face increasing pressure to deliver consistent, high-quality products at scale. Manual infusion techniques, while effective on a small scale, often fall short in meeting these demands due to variability and limited throughput. Automated systems like Jiko address these challenges by combining precision technology with streamlined workflows, enabling manufacturers to enhance product uniformity, increase production speed, and maintain rigorous quality control standards. This shift toward automation reflects broader trends in cannabis manufacturing aimed at professionalizing and scaling the industry.

Understanding Pre-Roll Infusion Methods

Pre-roll infusion is a process where cannabis pre-rolls (joint-like products) are enhanced by adding concentrates such as oils, waxes, or other flavor elements. This process increases potency, improves flavor profiles, and offers a more consistent experience for consumers. The traditional approach to infusion involves manual labor, with skilled workers applying concentrates directly onto pre-rolls by hand. This manual method has been the industry standard for many years but comes with inherent limitations.

Manual Pre-Roll Infusion

Manual pre-roll infusion requires trained technicians to carefully apply cannabis concentrates onto or inside the pre-rolls. This can be done through dipping, drizzling, or injecting concentrates by hand, depending on the desired product characteristics. Although it allows for some customization and artistic control, manual infusion is labor-intensive, time-consuming, and inconsistent by nature.

The main challenges with manual pre-roll infusion include:

Inconsistent Dosage: Applying precise and uniform amounts of concentrate to each pre-roll is difficult, leading to variability in potency and quality.

Low Throughput: Since the process is labor-intensive, production volumes tend to be limited, constraining scalability for larger operations.

Higher Labor Costs: Skilled workers are required for careful handling, increasing operational expenses.

Quality Control Issues: The manual nature increases the likelihood of human error, such as spills, uneven coating, or damage to the pre-rolls.

Limited Sanitation: Manual handling can introduce contamination risks, impacting product safety and shelf life.

These limitations highlight the need for automation in pre-roll infusion to improve consistency, speed, and hygiene.

Jiko Automated Pre-Roll Infusion

The Jiko Automated Pre-Roll Infusion system was designed to address the shortcomings of manual methods. By leveraging automation and precision engineering, Jiko provides a scalable, consistent, and efficient solution for cannabis producers aiming to infuse pre-rolls with concentrates.

Jiko’s core capabilities include:

Precision Application: The system can accurately meter and apply consistent doses of concentrate to each pre-roll, eliminating dosage variability.

High Throughput: Automation allows for rapid processing of large batches, significantly increasing production capacity.

Sanitary Operation: Reduced human contact lowers contamination risks and maintains higher product quality standards.

User-Friendly Interface: Operators can control infusion parameters digitally, enabling customization and repeatability.

Waste Reduction: Precise dosing minimizes concentrate waste, improving cost efficiency.

By integrating these features, Jiko aims to streamline the infusion process while enhancing the end-user experience.

Comparison of Efficiency and Consistency

A major advantage of the Jiko Automated Pre-Roll Infusion system over manual methods is operational efficiency. Manual infusion is inherently slower, constrained by human dexterity and fatigue. In contrast, Jiko can infuse hundreds or thousands of pre-rolls per hour with uniform dosing, supporting high-volume production.

Consistency is another critical differentiator. Variability in manual infusion can frustrate consumers who expect a uniform effect and flavor. Jiko’s automation ensures each pre-roll meets precise potency and flavor specifications, reinforcing brand reliability.

Moreover, automated systems like Jiko reduce the margin of error that comes with manual labor, such as accidental over-application or under-application of concentrates, which can affect the product’s quality and regulatory compliance.

Impact on Cost and Labor

While the initial investment in an automated system like Jiko may be significant, it often leads to long-term cost savings. Manual infusion demands a larger workforce and pays for skilled labor, which can be expensive and difficult to retain. Over time, automation reduces labor costs by streamlining production workflows.

Furthermore, automation decreases material waste. Manual application can lead to lost product through spillage or inconsistent dosing. Jiko’s precision reduces concentrate loss, improving profitability for manufacturers.

However, companies must consider the upfront capital expenditure, maintenance, and training required to operate automated equipment. In contrast, manual methods have lower initial costs but higher ongoing labor expenses and limited scalability.

Quality Control and Product Safety

Automated infusion systems improve quality control by standardizing processes. Jiko enables digital tracking of infusion parameters, which helps maintain compliance with industry regulations and quality standards. This data-driven approach facilitates traceability and accountability, which are increasingly important in regulated cannabis markets.

Sanitation is also enhanced with automation. Manual handling exposes products to potential contaminants, whereas Jiko minimizes human contact through enclosed, automated dosing. This reduction in contamination risk can extend product shelf life and improve consumer safety.

Customization and Flexibility

One potential limitation of automated infusion systems is reduced flexibility compared to manual methods. Skilled artisans can experiment with unique application techniques or small batch runs using manual infusion. Jiko, while customizable through software, may not replicate the artisanal touch or accommodate extremely niche infusion styles without additional programming or tooling.

However, many cannabis producers find that the benefits of scalability and consistency outweigh the slight reduction in customization. Moreover, Jiko’s interface allows adjustment of dosage levels and infusion patterns, which can satisfy most production needs.

Sustainability Benefits of Automated Pre-Roll Infusion

Automating pre-roll infusion can contribute to sustainability goals by minimizing waste and energy use. Precise dosing reduces overuse of concentrates, lowering resource consumption. Additionally, automated systems may optimize energy efficiency compared to prolonged manual labor sessions, contributing to a smaller environmental footprint.

This contrasts with manual methods, where inefficient application and higher waste generation are common. Companies aiming for greener production can find automated infusion beneficial for meeting sustainability benchmarks.

Industry Adoption and Future Outlook

As cannabis markets mature, the demand for high-quality, consistent, and scalable infused products continues to grow. Automated pre-roll infusion systems like Jiko are increasingly adopted by producers seeking competitive advantages. The ability to produce uniform products at scale while reducing costs aligns with industry trends toward consolidation and professionalism.

Looking forward, advancements in infusion technology will likely enhance customization options and integration with other automated systems. The trend toward full production line automation, including rolling, infusing, packaging, and labeling, will further reshape cannabis manufacturing.

Conclusion

The comparison between Jiko Automated Pre-Roll Infusion and manual pre-roll infusion methods reveals clear advantages for automation in the cannabis industry. Jiko offers superior consistency, higher throughput, improved quality control, and long-term cost efficiencies compared to manual techniques. While manual infusion allows for artisanal customization, it struggles with scalability, labor costs, and product variability.

For cannabis producers looking to optimize their infusion processes, investing in automated systems like Jiko provides tangible benefits that enhance operational efficiency and consumer satisfaction. The shift towards automation marks a pivotal evolution in how infused pre-rolls are produced, supporting the growing demand for premium cannabis products.

FAQs

What are the main benefits of automated pre-roll infusion compared to manual methods?

Automated infusion offers precise dosing, higher production speed, improved sanitation, consistent product quality, and reduced labor costs.

Does automated infusion limit product customization?

While automation standardizes processes, modern systems like Jiko allow adjustments to dosage and infusion patterns, offering flexibility for most production needs.

How does automated infusion impact product safety?

By minimizing human contact and standardizing processes, automation reduces contamination risk and enhances compliance with safety regulations.

Is investing in an automated pre-roll infusion system cost-effective?

Though initial costs can be high, automation often reduces labor expenses, decreases waste, and supports scalability, leading to long-term savings.

Can automated infusion systems handle different types of concentrates?

Yes, advanced systems are designed to work with various cannabis concentrates and can be calibrated for different viscosities and formulations.