What Is Five Axis Machining?

Unlike traditional 3-axis machines, which move along the X, Y, and Z axes, Five Axis Machining adds two additional rotary axes. This enables the cutting tool to approach the workpiece from virtually any direction, allowing complex shapes and angles to be created in a single setup.

Here’s a quick overview of the axes:

X, Y, Z – Linear movement

A Axis – Rotation around the X-axis

B or C Axis – Rotation around the Y or Z-axis

View high-precision five axis systems here:

? Five Axis Machining

Why Five Axis Is a Game Changer

The key advantage of five-axis technology lies in its ability to reduce setups, increase machining accuracy, and manufacture more complex parts. Traditional machines often require multiple setups to achieve different angles or sides. With five-axis, all faces can be machined in a single go.

Core Benefits of Five Axis Machining

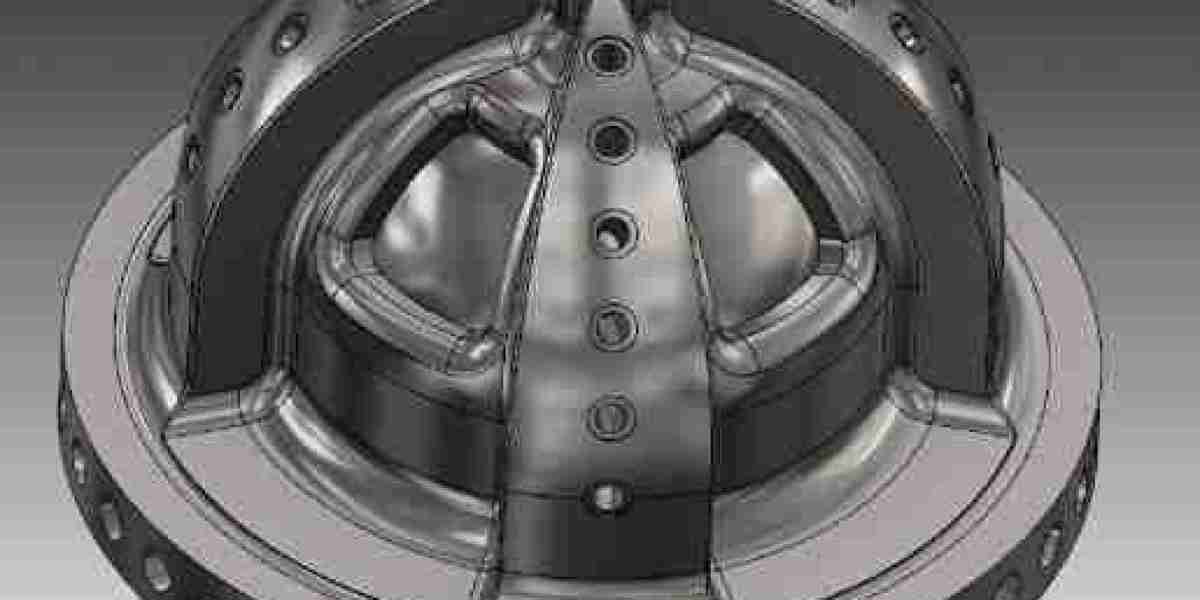

✅ Complex Geometry Made Easy

Perfect for components that require tight tolerances and intricate detailing, like turbine blades, medical implants, or aerospace parts.

✅ Fewer Setups

Single-setup machining eliminates repositioning errors and saves time.

✅ Better Surface Finish

Tool orientation can be optimized, allowing smoother cuts and finer finishes.

✅ Higher Accuracy

By maintaining the same reference point, dimensional integrity is preserved across the part.

✅ Reduced Tool Wear

Optimal angle positioning means more efficient cutting, less tool stress, and longer tool life.

Industries Benefiting from Five Axis Machining

The versatility of Five Axis Machining makes it suitable for a wide range of sectors:

Aerospace – For lightweight, high-strength, and aerodynamically optimized parts

Medical – For prosthetics, implants, and surgical components

Automotive – For precision engine parts, custom tooling, and mold making

Defense – For advanced weaponry, optical systems, and guidance components

Die and Mold Making – For detailed and deep mold cavities

Why Choose keytexmachines?

When it comes to adopting five-axis technology, precision engineering and machine reliability are critical. That’s where keytexmachines comes in. Known for delivering high-performance machining solutions, they specialize in five-axis systems that are built for durability, consistency, and performance under demanding industrial conditions.

Whether you're a small shop looking to take on complex jobs or a large enterprise scaling high-volume production, keytexmachines provides robust five-axis solutions tailored to your needs.

The Future of Manufacturing

As components continue to get smaller, lighter, and more complex, the reliance on Five Axis Machining will only grow. Coupled with automation and smart software integration, this technology is pushing the boundaries of what's possible in manufacturing.

From prototyping to full-scale production, five-axis is becoming an essential part of modern machining strategy. It not only helps meet today’s design complexity but also prepares manufacturers for the challenges of tomorrow.

Final Thoughts

If your business demands high-precision, fast turnaround times, and flexibility in machining—Five Axis Machining is your go-to solution. It offers freedom in design, efficiency in execution, and excellence in results.

Upgrade your manufacturing capability by incorporating five-axis systems that bring your most complex ideas to life—with accuracy, speed, and confidence.